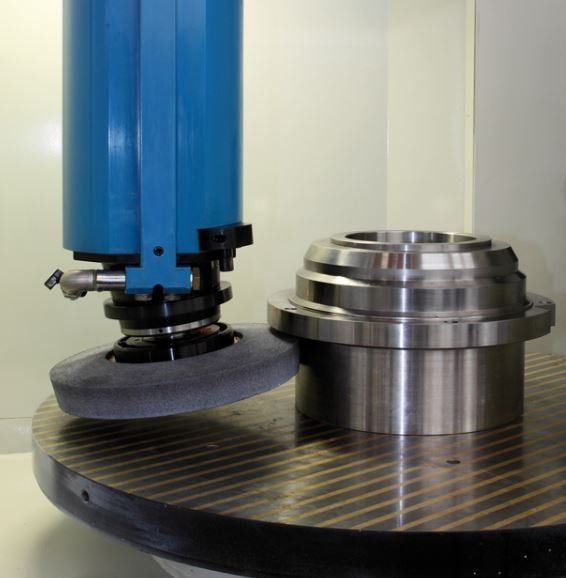

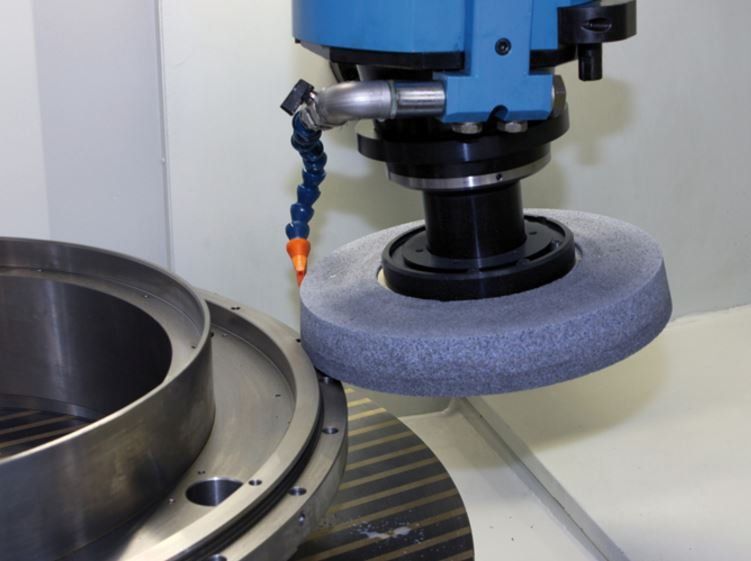

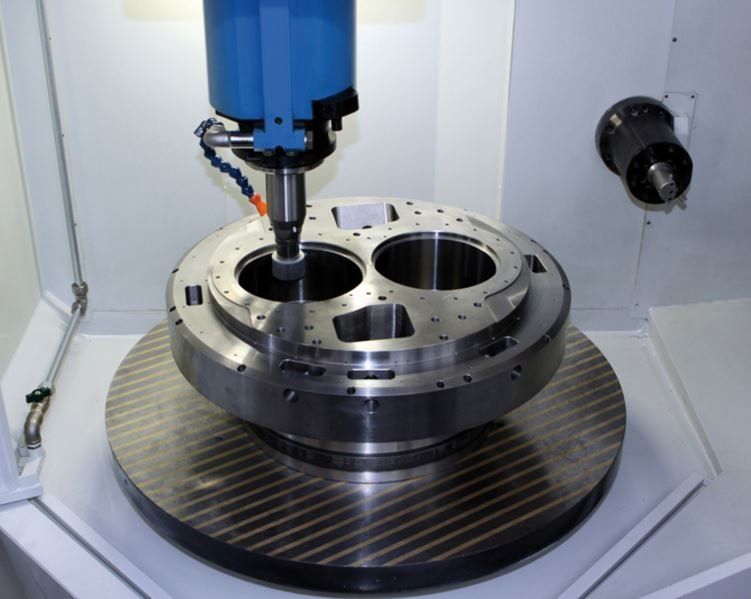

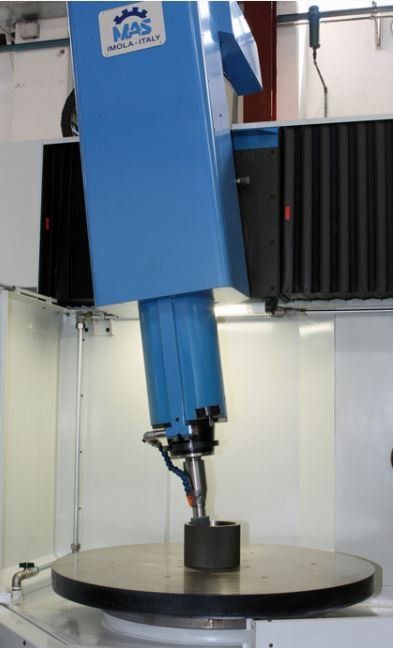

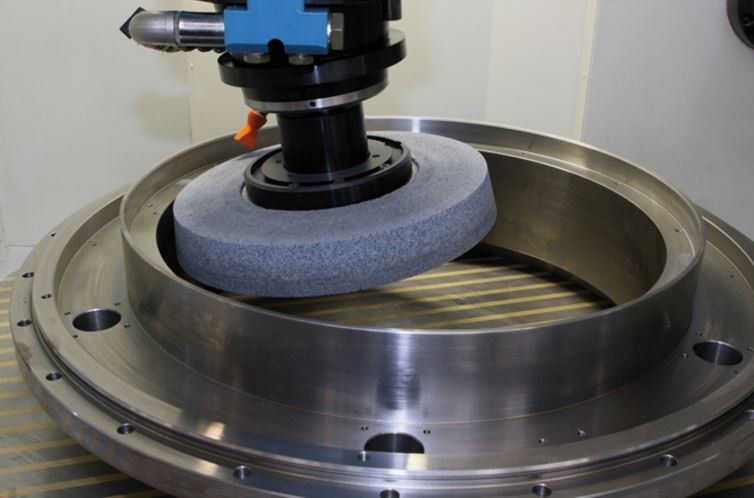

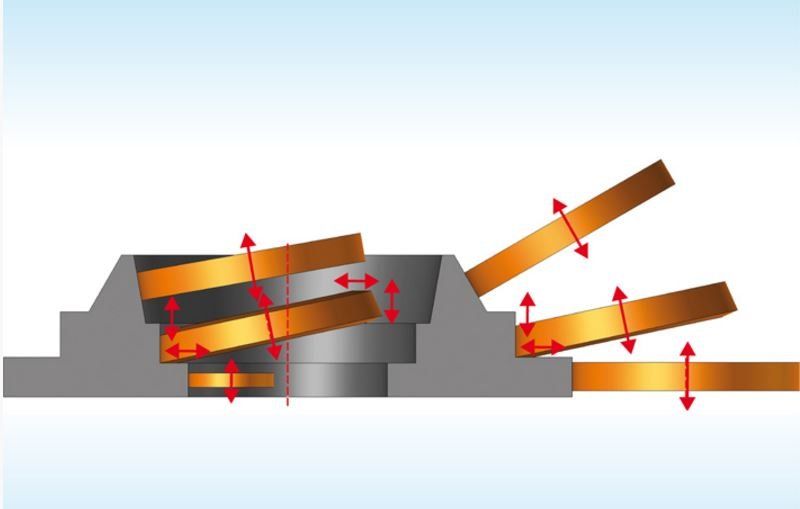

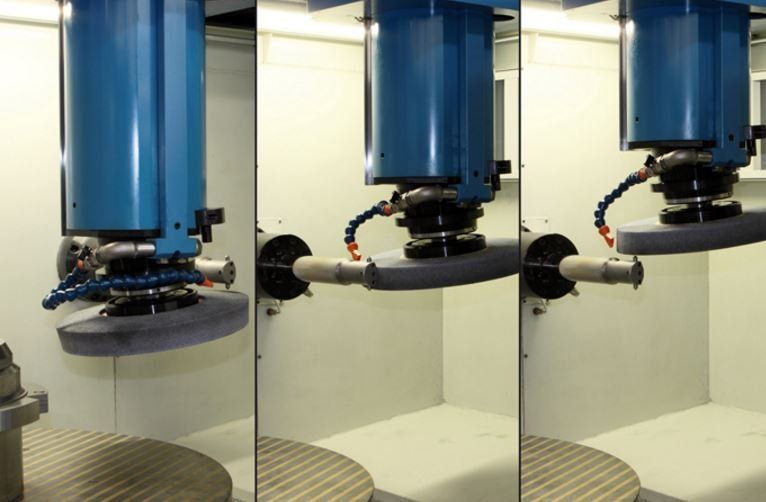

At the MAS Srl, we have VGM available. This is a small and compact machine that allows the external and internal grinding of large workpieces. Equipped with an electro-spindle, the grinding wheel axis can be manually tilted in a few minutes and allows the machine, by "profiling the grinding wheel", to grind diameters and surfaces on the beltway without the need to separate / elevate the piece from the magnetic surface, thus reducing the placement times.

A bevel of just 0.2 millimetres is, in fact, sufficient to carry out grounding of diameters without having to elevate the piece. VGM is suitable for small high-precision production lots and can be equipped with the fourth axis to grind cam profiles and complex shapes.

The machine is equipped with:

- Siemens numerical control;

- Filter;

- Electro-spindle cooling system;

- Automatic grinding wheel dressing cycle;

- Temperature control probes.

Optional:

- Fumes extraction system

- 4th axis;

- Touch probe;

- Storage tools;

- Magnetic Plane;

- Dressing roller.

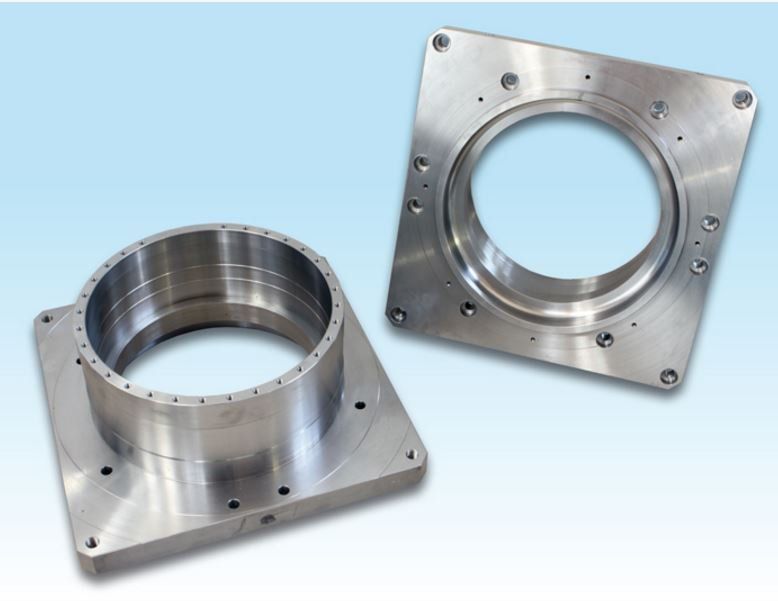

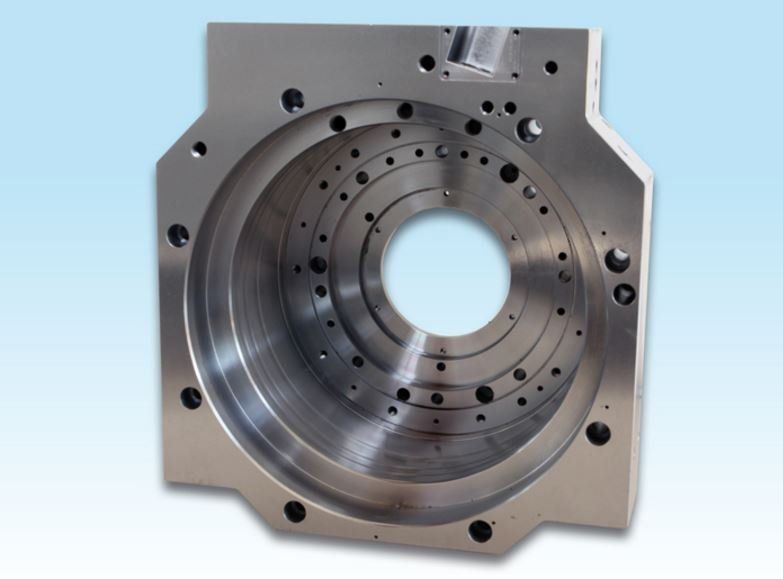

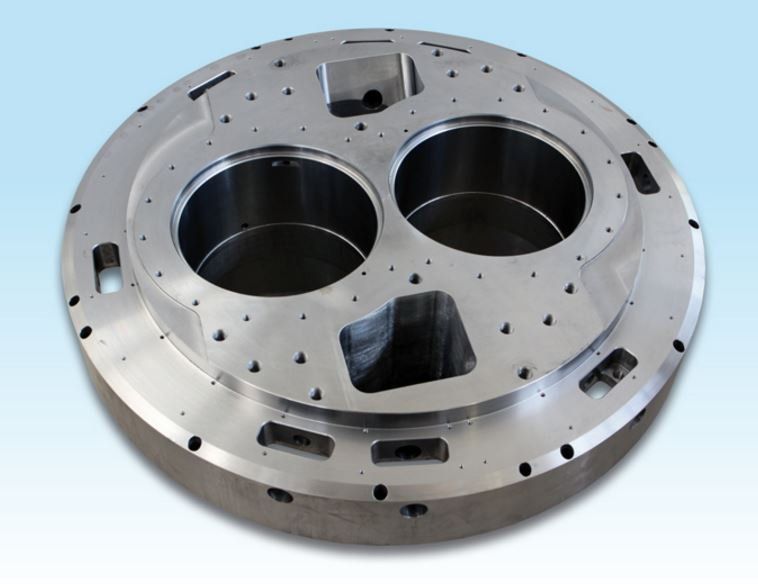

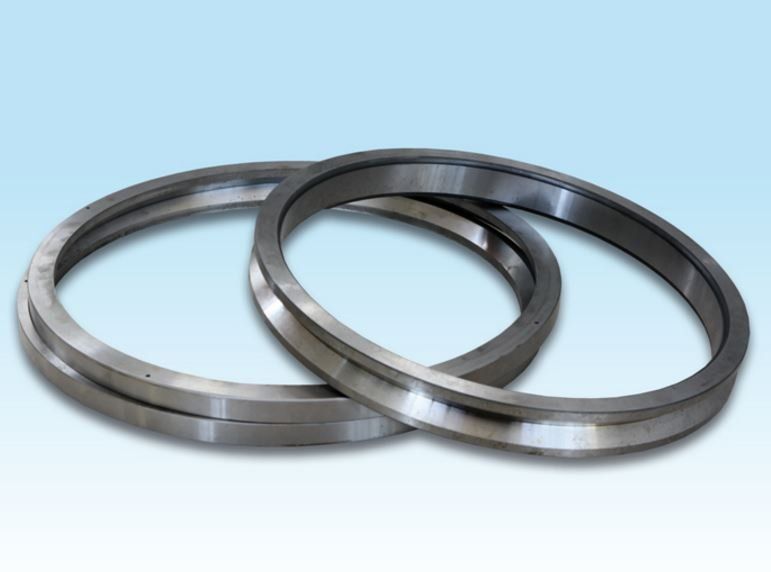

Sectors of use VGM:

- Wind;

- Naval;

- Oil & Gas;

- Automotive;

- Aero-space;

- and more...