MAS Honing systems The jewel in our crown

MAS Srl is located in Imola and is a trusted partner for precision mechanical machining processes. In the sections below you can find out more about our strengths and the quality of the services that we offer.

HONING SYSTEM

MAS Honing systems are able to:

• to work cast iron, treated and untreated steels, stainless steel, sintered metal, aluminium, carbon fibres, light alloys, metal ferrites and ceramics;

• produce any type of hole (through-hole, dummy hole, with seat or spline) diameter can vary between 4 and 60 mm and up to 400 mm in length.

Download PDF

• to work cast iron, treated and untreated steels, stainless steel, sintered metal, aluminium, carbon fibres, light alloys, metal ferrites and ceramics;

• produce any type of hole (through-hole, dummy hole, with seat or spline) diameter can vary between 4 and 60 mm and up to 400 mm in length.

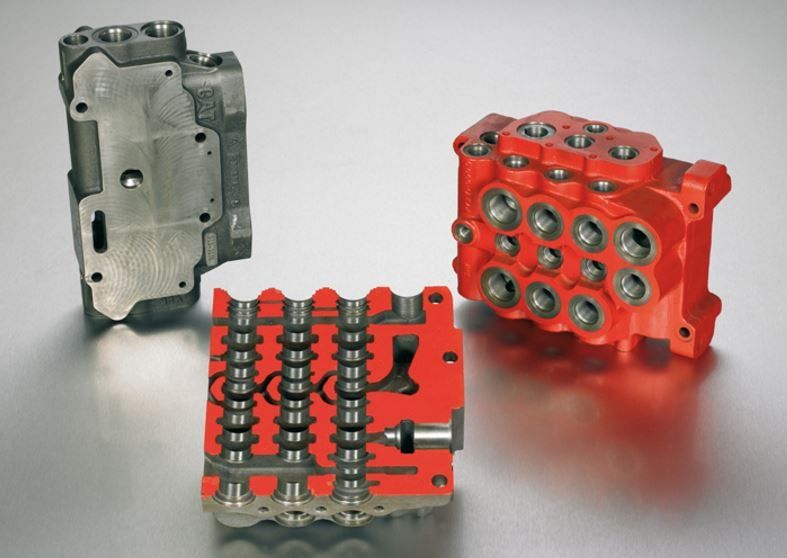

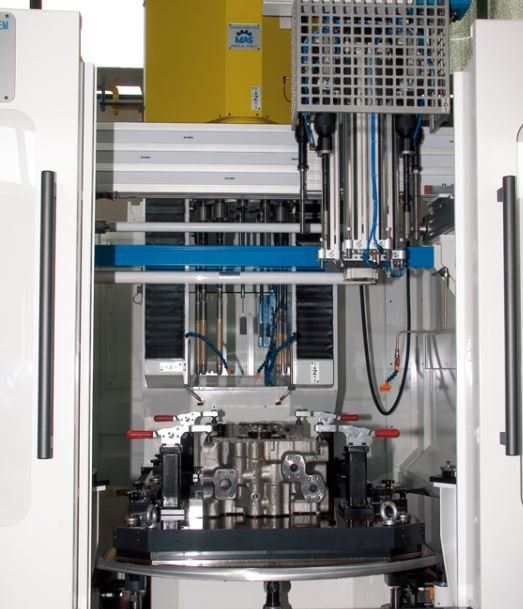

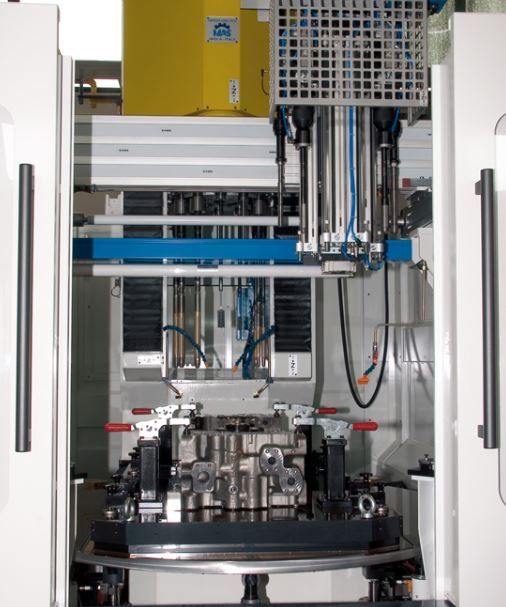

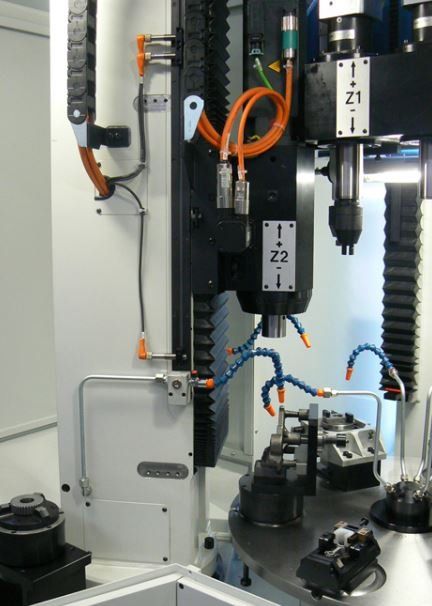

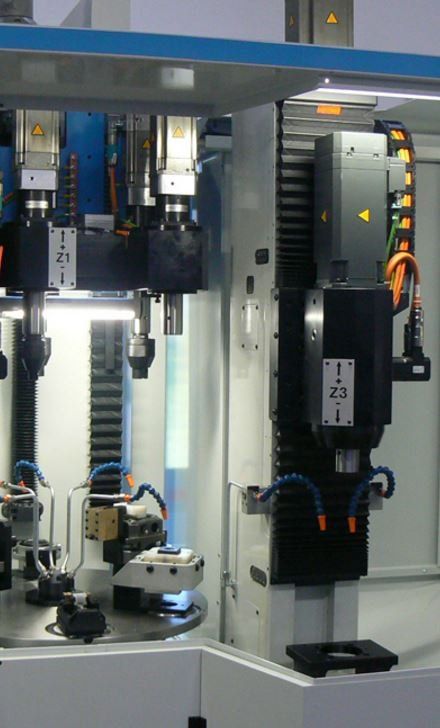

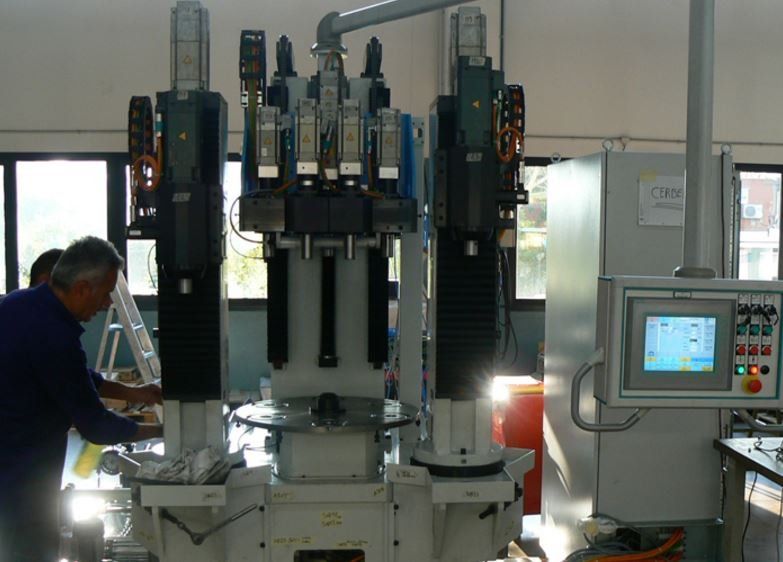

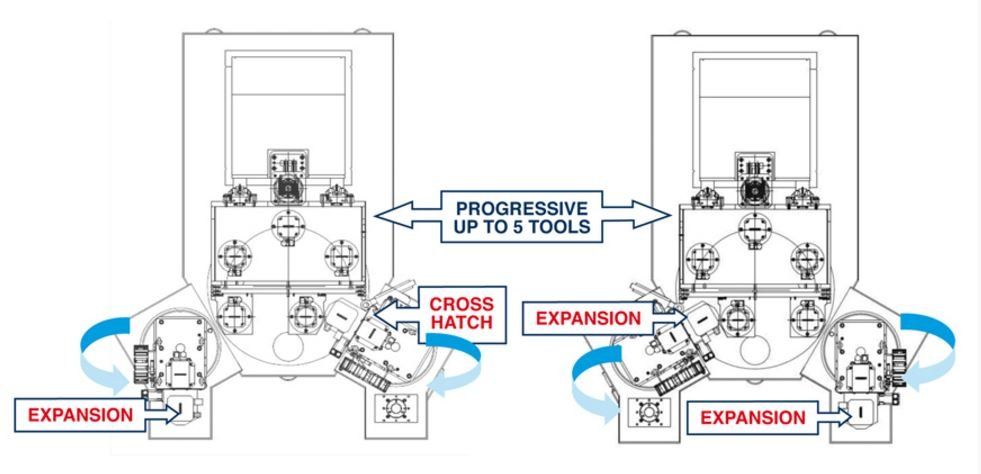

Honing systems: Progressive

MAS progressive honing machines ensure the highest precision in joining and finishing when dealing with precision mechanical machining processes for producing both medium and large parts.

There are both rotary or linear table machines from 1 to 24 stations, equipped with workpiece locking systems, spindles and floating rods to adjust tools and to manage CNC and PLC of all sizes. MAS machines ensure every single bore is produced to one single finished size, giving excellent results in roundness, cylindricity, taper, straightness and roughness. The honing machines are equipped with oil filtration and cooling systems.

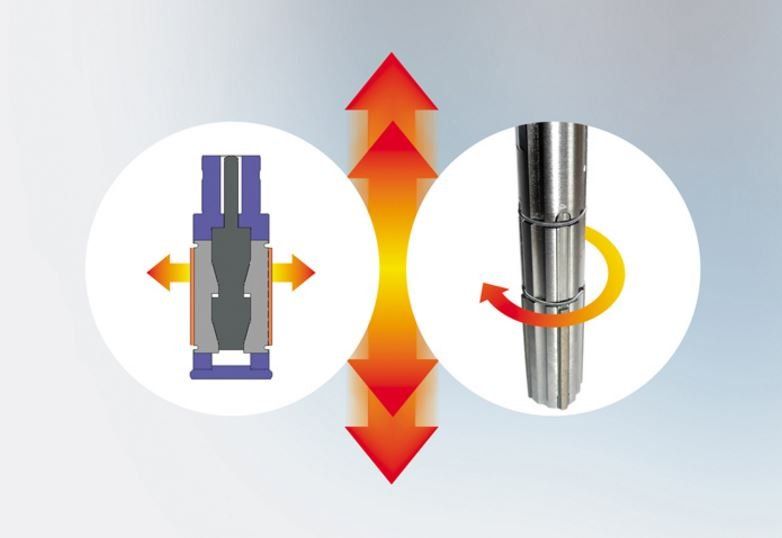

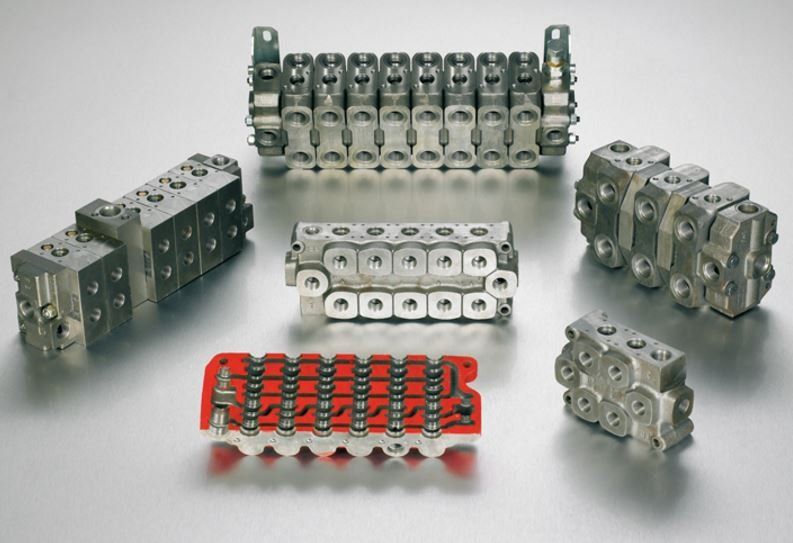

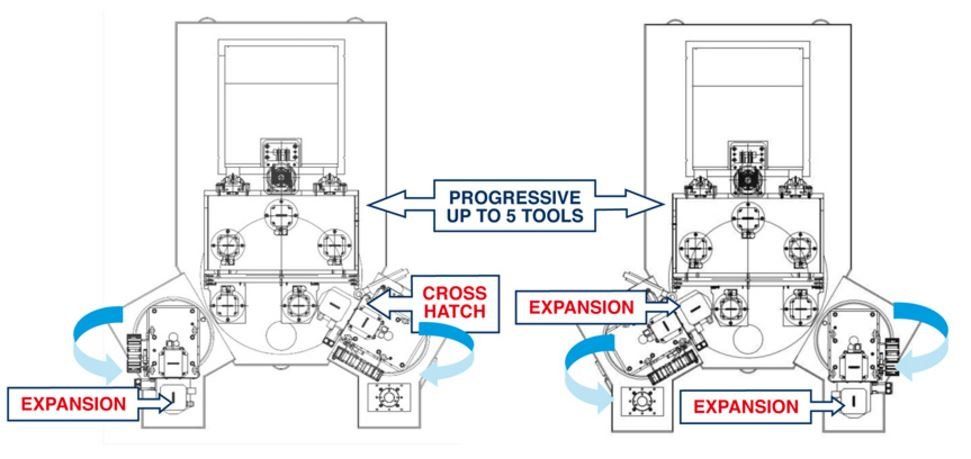

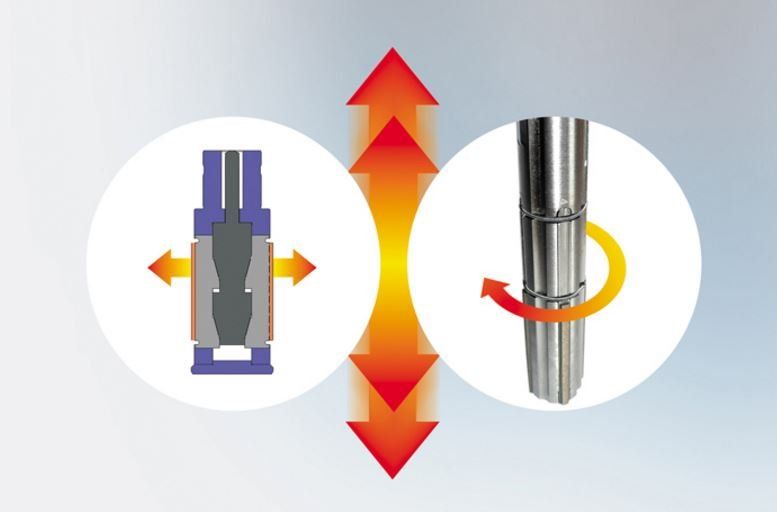

Honing systems: Expansion

MAS has developed and manufactured a modern flexible and modular honing system that guarantees flexible solutions to any lapping needs.

It consists of expansion lapping modules that can be used in combination with progressive honing systems or as single expansion lapping units.

The expansion module was designed to remove / roughen large quantities of material and to create cross-cutting. The processing capacity ranges from ø 5 to ø 100 mm.